In a small village in Baden-Württemberg, the recycling containers, known as ‘yellow bins,’ are awaiting their scheduled collection. As is customary in this region, residents have placed their bins neatly and precisely at the side of the road. In Germany, people take pride in their recycling culture, or ‘waste separation,’ as it is commonly known. Paper, recyclables, glass, organic waste, and residual waste are all carefully sorted and collected to ensure that as much as possible is recycled. The system extends well beyond private households. Even at a construction site for a new Kaufland store, waste is meticulously separated.

THE CRADLE-TO-CRADLE PRINCIPLE AT KAUFLAND

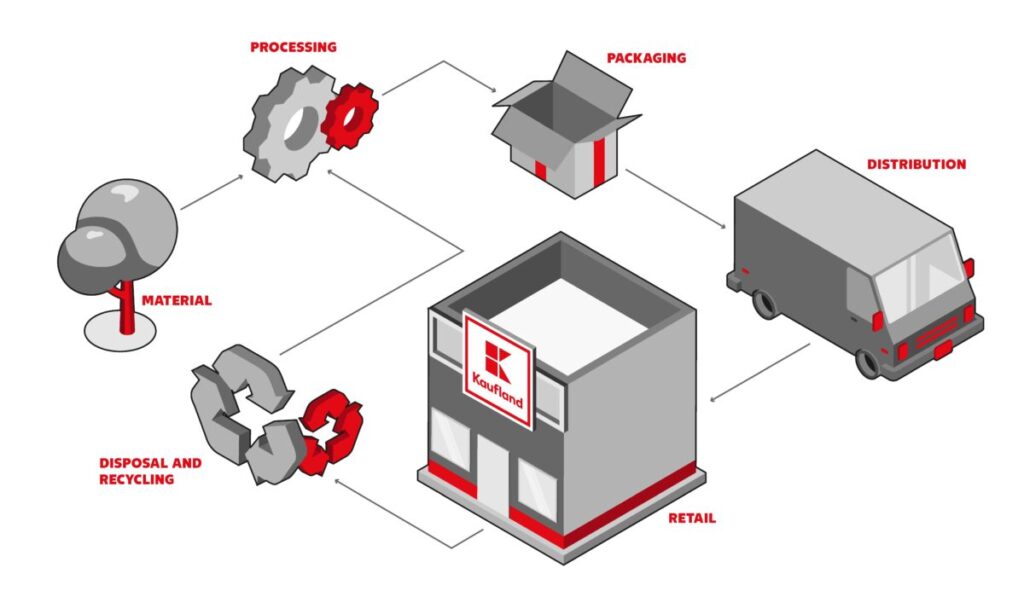

The construction and real estate industry accounts for a significant share of global resource consumption. According to the German Council for Sustainable Development, it is responsible for nearly 40% of CO₂ emissions and generates around 60% of all waste. This impact makes the sector a powerful lever for change – and the catalyst for Kaufland’s guiding principle of sustainable construction. Sustainability in construction goes far beyond reducing CO₂ emissions. Climate protection is essential, but it is only one piece of a larger picture. Issues such as soil sealing, environmental protection, biodiversity loss, and the careful use of resources must also be addressed. That is why Kaufland takes a cradle-to-cradle approach, considering every property across its entire life cycle—from construction to demolition. The careful selection of materials ensures that environmental impact is kept to a minimum while energy and resource consumption are reduced as much as possible.

Kaufland focuses on efficient technologies, renewable energy, electric vehicle charging infrastructure, biodiversity, sustainable building materials, and much more. The basis for this is the green building concept, defined by sustainable construction methods and technology. A central pillar of this concept is the use of sustainable building materials and a commitment to recyclable construction — in short, the cradle-tocradle principle. This principle states that built resources are not wasted but continuously returned to the cycle.

As in nature, buildings constructed and demolished according to this principle become the foundation of something new and thus part of a cycle. It is, in many ways, a radical idea. It challenges the logic of the throwaway society and instead promotes a world in which everything deemed “no longer needed” is either technically or biologically recycled. In such a system, the very notion of waste would all but disappear. At its core, cradle to cradle is based on five criteria: material health, product circularity, clean air and climate protection, water and soil stewardship, and social fairness.

When the five cradle-to-cradle criteria are applied to construction, they translate into four guiding principles that a property must fulfil:

- Over its life cycle, the property must generate at least as much energy as it consumes.

- All dismantled materials must be reusable for new construction, other purposes, or fully compostable.

- Interiors must promote healthy living conditions, and production processes must adhere to social standards.

- Instead of releasing harmful and toxic substances into the environment, the property should filter pollutants and water through its façade.

By using recycled building materials, Kaufland helps to conserve natural resources and reduce environmental damage. At the same time, the company also prioritizes the use of local building materials, eliminating long transport distances and supporting local businesses. New materials are regularly tested for sustainability, CO₂ equivalence, recyclability, durability, and cost-effectiveness. The range of materials is broad and includes recycled paving stones, bricks produced from construction waste, fibreboards crafted from recycled cellulose, glass-ceramic panels made from waste glass, and mineral fibre insulation derived from recycled content.

BUT HOW EXACTLY DOES WASTE BECOME A VALUABLE BUILDING MATERIAL?

Early in the morning, a white waste collection vehicle with the inscription ‘PreZero’ turns into the street of the small village in Baden- Württemberg. Clattering and rumbling, it empties one yellow bin after another. Inside go the lightweight packaging items—plastic bags, plastic bottles, beverage cartons and tin cans. For the households that set them out, these are simply things to be discarded. For those collecting it, however, it is raw material from which something new can be created.

Turning waste into a new raw material takes several steps. Essentially, it is about closing the recycling loop—and that starts with proper disposal by consumers. When households or companies sort their waste correctly, materials can be reused according to their composition and remain in the cycle. To this end, the white waste collection vehicle takes the collected recyclables to a sorting plant. There, a combination of manual work and state-of-the-art technology

separates the waste by type and prepares it for the next stage: producing new recyclates. This marks the shift from a linear to a circular system. This process step takes place in one of three PreZero’s grinding plants. The result is a raw material that can be used to manufacture new packaging, household products, toys or even new building materials. And the process goes far beyond plastics — aluminium, glass, green waste, wood, and construction debris can all be reprocessed with added value. The fundamental goal is to process materials for further use.

The environmental services provider PreZero, which owns the waste collection vehicles and the grinding plants, is, like Kaufland, a member of the Schwarz Group. And this is precisely where the uniqueness of the approach along the entire value chain becomes apparent. Working hand in hand with its sister company, Kaufland can close many steps in the value chain — from disposal, collection, and processing to supply to reuse as new building material.

What does this mean in practice? It begins with a goal—one that challenges the status quo, embraces new ways of thinking, and takes responsibility for improving what already exists. With this mindset, Kaufland has defined an overarching objective: to create a fully circular store. At the same time, the company is working toward another key goal—developing building materials from its own closed cycle.

The road to a fully circular store may still be long— but it has already begun. Kaufland is now identifying materials within its real estate that can be redesigned and produced from its own ecosystem. One example is a newly developed impact protection system. The original product was made from primary raw materials—an enormous use of resources for an item designed to protect walls or technical equipment from damage. Kaufland’s idea: rethink the choice of materials. Two alternatives were explored— manufacturing the system from recycled plastic or from the renewable raw material wood. The concept is then put to the test in real-life operation.

The result: Kaufland is now using a newly developed impact protection system that requires 80% less new material and is made primarily from recycled content. What makes it even more remarkable is that it incorporates recycled raw materials that are otherwise difficult to reuse— such as thin-walled plastic bottles. And the best part? The sustainable version is actually cheaper than its conventional counterpart—a clear example that sustainability doesn’t always come at a higher cost.

Another example is the development of roofing membranes, made partly from the company’s own supermarket film and partly from recycled material, saving a large amount of material and CO₂. Looking ahead, Kaufland’s goal is to implement a fully recyclable roof for its properties. This would include the roofing membrane, mineral wool insulation, vapour barrier, and even the fasteners.

In order to process the recycled material—sourced partly from household waste in Baden-Württemberg—into usable building products, Kaufland works with experienced manufacturers who share its vision. Together with these partners, the company finds ways to design, develop, and manufacture the desired solutions. The process is seamless: PreZero supplies the circular raw materials, the manufacturer develops, refines and produces them, and Kaufland integrates the final product into its stores. The result is a fully closed recycling loop—circular from start to finish.

And the journey is far from over: Kaufland’s catalogue of ideas for new product developments is already overflowing. Yet bringing them to life requires more than just the sometimes lengthy processes of development and production. Equally crucial are flexible approval procedures for individual products, coupled with and clear legislation that support the use of circular and recycled building materials. One possible approach is individual approvals, which would minimise risks in construction and encourage broader adoption of circular building materials. Such measures could make an active contribution to reducing the high volume of waste and CO₂ emissions generated by the construction and real estate industry!

Until then, the white PreZero waste trucks will continue to collect recyclable materials from households, transforming what is considered waste into valuable new raw materials and closing the recycling loop – because Europe’s future lies in recycling!

SUSTAINABILITY AT KAUFLAND

As part of the Schwarz Group, Kaufland has been pursuing ambitious reduction targets since 2019. Now the company is taking the next bold step: cutting greenhouse gas emissions across the entire value chain, with the aim of reaching net zero by 2050 at the latest. It is a groundbreaking commitment by the group for the climate, for the environment, and for future generations. Significant progress has already been made. Since 2019, Kaufland has reduced its operational CO₂ emissions by 67 %. The real estate sector plays a central role in achieving sustainability goals, as construction, development, and store operations account for a major share of the footprint. To this end, Kaufland is making its stores increasingly energy-efficient and sourcing 100 % green electricity (with the exception of supply contracts over which, it has no influence, such as certain leased properties with existing electricity supply agreements).

Dominik Uhe

Head of Investor Relationship Management at Kaufland International

Credit for all images: Kaufland